Workplace Safety First

One of the goals of facility maintenance programs is to avoid problems before they occur. When a reactive approach to maintenance is taken, tasks are not scheduled until components break and systems fail. A proactive approach focuses on preventing system degradation and failure through regularly scheduled maintenance to keep systems clean, in good repair, and running smoothly.

Most facilities have many systems including heating and cooling, electrical, mechanical, and plumbing. Part of being proactive is creating a comprehensive maintenance checklist and implementing your preventative maintenance program before systems fail.

Begin by taking inventory of all the equipment and systems in your facility. Record pertinent information such as model name and number, installation date, specifications, and functions. Identify preventative maintenance needed and determine how often maintenance needs to be performed. Standardized sets of requirements and work practices, with clear instructions, are good practices to have in place to be used by all maintenance workers. Clear instructions, proper equipment and tools, and appropriate personal protection equipment are all important to providing a safer environment for maintenance workers.

Having a proactive maintenance plan in place will save money and time. Proper maintenance is cost-effective and helps keep all the systems in your facility performing at their best, leading to increased productivity and efficiency.

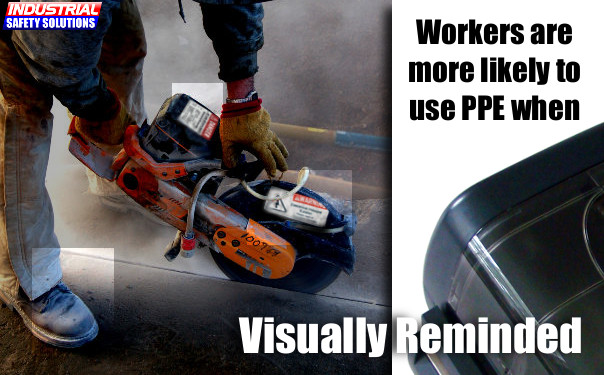

No proactive maintenance program is complete without safety labeling. Facility maintenance is an important task, and proper labels and signs can make that task easier. Properly placed labels provide the vital information maintenance workers need to be able to perform their tasks with greater efficiency and increased safety. In addition to improving visual safety and reducing accidents, custom labels are also used to label service schedules and safety routines.

To meet the demands of your proactive facility maintenance program, you should consider purchasing a SafetyPro label printer that will let you create custom labels when you want them, in the qualities you need. By printing custom labels for your facility instead of ordering from a catalog, you will save time and money, and you will be able to more accurately meet the specific needs of your facility. Make safety labeling a part of your proactive maintenance program with the SafetyPro facility maintenance label printer.